In the world of industrial automation, robot arms are the backbone of modern production lines. Whether used for welding, assembly, material handling, or packaging, these robotic systems rely on a critical yet often overlooked component: Robot Cables. Without high-quality cables, even the most advanced robotic arm cannot perform reliably. So, why does a robot arm need cables, and what types are commonly used in the industry?

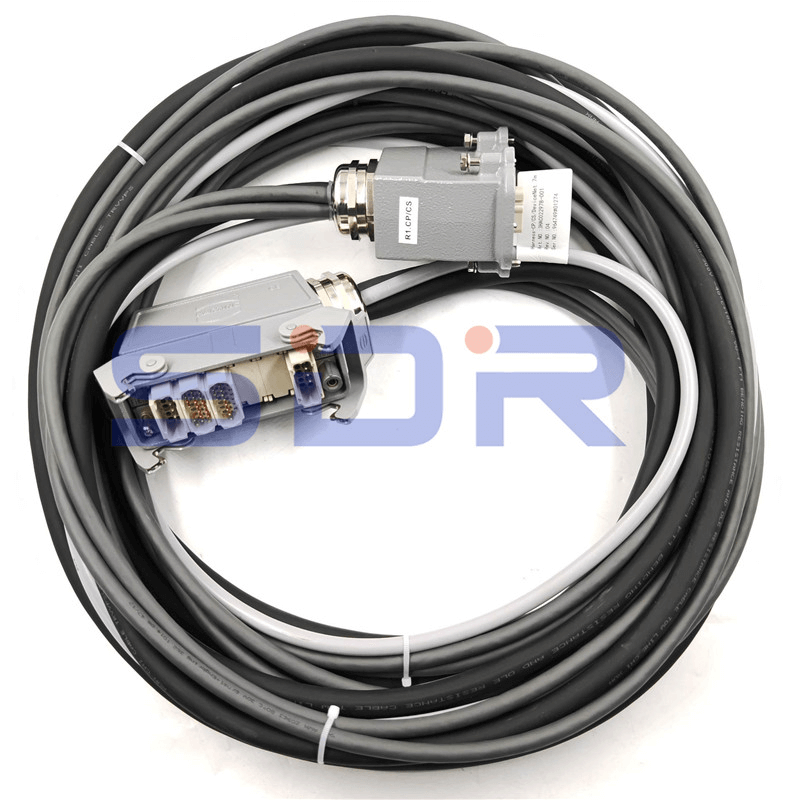

A robot arm requires both electrical power and control signals to function. Servo motor cables deliver the necessary power to the motors located in each joint of the arm, while industrial robot connectors ensure stable signal transmission between the controller and the robot. These cables allow for precise movements, coordination, and safe operation.

Unlike standard electrical wiring, Robot Cables must withstand constant bending, twisting, and dynamic motion. For example:

Fanuc Robot Cables are designed for long life and consistent performance in demanding manufacturing environments.

KUKA Robot Cables and ABB Robot Cables provide robust connectivity for welding and assembly applications.

YASKAWA Robot Cables and KAWASAKI Robot Cables are engineered for heavy-duty robotic systems in automotive and industrial sectors.

OTC Robot Cables and NACHI Robot Cables are optimized for robotic welding systems where stable communication and power supply are essential.

EPSON Robot Cables and COMAU Robot Cables offer reliable performance for precision robotic arms used in electronics and automation.

Each manufacturer provides cables tailored to their robots, but all share the same purpose: enabling the robot arm to operate efficiently and reliably.

Robot arms operate in environments where precision and safety are crucial. High-quality servo motor cables and industrial robot connectors ensure that signals are not interrupted, avoiding downtime and maintaining production safety. Proper shielding also prevents electromagnetic interference (EMI), ensuring reliable communication between the robot controller and its actuators.

The question “Why does a robot arm need cables?” has a simple answer: without cables, the robot cannot move, communicate, or perform its tasks. From Fanuc Robot Cables to KUKA, ABB, YASKAWA, KAWASAKI, OTC, NACHI, EPSON, and COMAU Robot Cables, each solution is engineered for specific robotic systems. With durable servo motor cables and secure industrial robot connectors, robot arms achieve the flexibility, precision, and reliability required in today’s industrial automation.