In modern industrial automation, reliable power transmission and signal integrity are crucial for the performance of robotic systems. ABB Robot Power Line and Robot Cables serve as the lifeline for ABB robots, providing stable power supply and smooth communication between robot controllers and end-effectors. To meet the diverse requirements of different industrial applications, customization of these cables has become increasingly important. ABB Robot Power Line Robot Cable Customization ensures that every cable meets the unique demands of a specific robotic setup, improving operational efficiency and reducing downtime.

High Flexibility and Durability

These cables are designed for continuous movement in robotic arms, with high flexibility to withstand torsion, bending, and extension.

Materials such as high-quality copper conductors and abrasion-resistant jackets ensure a long service life even under harsh industrial conditions.

Excellent Electrical Performance

Optimized for low voltage drop and stable current transmission.

Shielded designs prevent electromagnetic interference (EMI), ensuring precise control of the robot.

Suitable for both power supply and signal transmission in ABB robotic systems.

Customizable Design

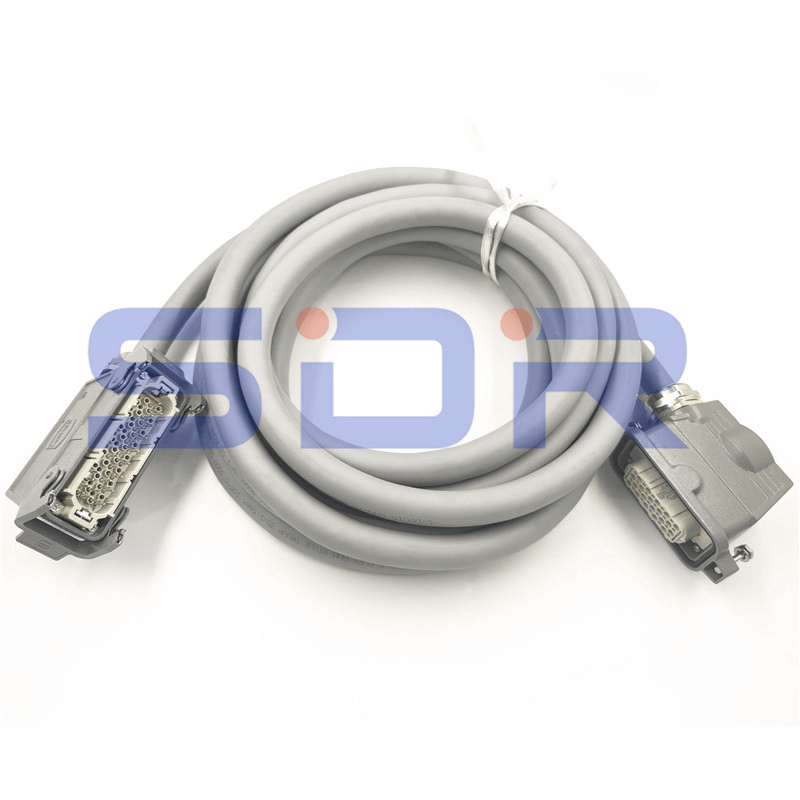

ABB Robot Power Line Robot Cable Customization allows clients to select length, connector types, conductor sizes, shielding, and jacket materials.

Custom cables can be designed to meet extreme temperatures, high-speed motion, or specific chemical and environmental resistances.

Safety and Compliance

Cables comply with international standards such as UL, CE, and RoHS, ensuring safety and reliability in industrial operations.

Fire-retardant and wear-resistant options are available for demanding environments.

Optimized Performance: Tailored cable designs reduce resistance and interference, ensuring robots operate efficiently.

Extended Lifespan: Proper material selection and construction extend cable life and reduce maintenance costs.

Space Efficiency: Customized lengths and routing solutions prevent cable clutter and improve workspace organization.

Application-Specific Solutions: Cables can be adapted for welding robots, painting robots, pick-and-place systems, and collaborative robots.

Industrial Automation

ABB robotic arms in automotive assembly lines, electronics manufacturing, and packaging systems rely on reliable power and signal transmission.

Custom cables provide flexibility for multi-axis movement and high-speed operations.

Collaborative Robots (Cobots)

Lightweight, Flexible Robot Cables are essential for safety and smooth operation in human-robot collaborative environments.

Harsh Environment Robotics

Robots operating in chemical plants, outdoor applications, or extreme temperatures require specialized jackets and insulation materials for durability and safety.

Material Selection: Copper conductors for excellent conductivity, PVC/PU/TPE jackets for abrasion resistance, and shielding options for EMI protection.

Precision Assembly: Multi-core cables are carefully twisted and shielded to maintain signal integrity during dynamic motion.

Testing: Each customized cable undergoes electrical testing, flexibility testing, and environmental resistance testing to ensure reliability.

Connector Integration: Customized connectors are added according to client specifications, including screw-type, plug-in, or proprietary ABB connectors.

Regular Inspection: Check for visible wear, cracks, or abrasion on jackets.

Avoid Sharp Bends: Ensure that cables are routed to prevent excessive bending or twisting.

Clean Environment: Remove dust, oil, or chemical residues that may degrade cable material.

Replace Damaged Cables Promptly: Damaged robot cables can affect robot performance and safety.

ABB Robot Power Line Robot Cable Customization is essential for industrial automation systems to ensure optimal performance, longevity, and safety. Customized cables, including power lines and signal transmission cables, provide flexibility, durability, and compliance with industry standards. By choosing tailored solutions, manufacturers can enhance robot efficiency, reduce downtime, and meet the unique requirements of their production environment.

Previous: Fanuc Robot Cable